- Home

- Hydraulic components

- Settima Dealer

Settima Dealer

Settima produces screw pumps and helicoidal rotors in which the reduction of noise is the focal point thanks to extensive research and development. The result is that Settima pumps operate at a low noise level, but with a longer lifespan and increased reliability. Settima is an important supplier to the oil, gas and maritime industries.

Settima has more than 40 years of experience in producing low-noise pumps and over those 40 years, has produced more than 1,000,000 pumps. Settima has produced pioneering innovations designed to control pump noise. Its Continuum® technology is one of the most significant contributions to the hydraulic industry.

Helicoidal gear pumps

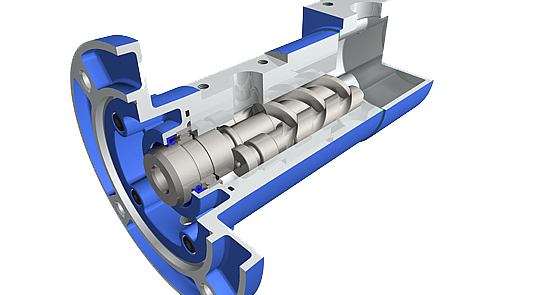

Settima Meccanica has developed, produced and patented the world's first no-noise gear pump with helicoidal rotors. Continuum® is the no-noise alternative for gear pumps and vane pumps and is ideal for high-pressure applications. Continuum® – the no-noise gear pump with helicoidal rotors – eliminates the causes of noise, thanks to a new sophisticated design and production.

NO-NOISE CONTINUUM® TECHNOLOGY

Unlike traditional gear pumps, the patented Continuum® helicoidal rotor profile does not block the oil, which results in a continuous exchange of oil and an exceptional reduction in pulsations.

Dry and submersible screw pumps for no-noise applications with low and medium pressure

SMT16B and SMT types are threefold screw pumps for industrial use with low and medium pressure (SMT16B = 40 bar and SMT = 80 bar). These screw pumps are durable, produce almost no noise and are used in industrial applications that require lengthy lifespans and low costs. The threefold screw design prevents axial load. The generated pressure ensures that the screws are hydro-dynamically balanced. At the same time, the screws and other parts are cooled and lubricated. The pumped liquid transfers the torque required to move the screws, which means that they can rotate without wear and tear.

The sophisticated design and high precision of the screws ensure a very low level of noise and pulsation. The geometry and high-precision finish of the threefold screws ensure enclosed chambers. While the three screws rotate, the main screw holds the liquid in a cavity and drives the liquid in an axial direction from the inlet to the outlet aperture.